Residual fuels are highly complex mixtures, containing a wide variety of components at different concentrations. ISO 8217

specifies the requirements for fuels for use in marine diesel engines and boilers prior to conventional onboard treatment,

and provides a list of specifications for several parameters.

However, there is no compiled list of all the chemical compounds expected to be found in marine fuels, or the specific concentrations of each component. In general, this is addressed in Clause 5 of ISO 8217, which states that

The fuel shall be free from any material that renders the fuel unacceptable for use in marine applications.” In particular, “it shall not contain … any added substance or chemical waste which jeopardizes the safety of ships or adversely affects the performance of the machinery…[1]

The wording of Clause 5 varies slightly across the different editions of ISO 8217, although the general idea remains the same, that is the fuel should not contain deleterious materials. However, the standard itself does not provide a specific test method for Clause 5.

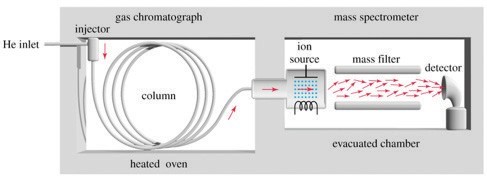

GC-MS is a widely used method for detecting chemical compounds, in particular those that are present in low concentration levels, in various kinds of sample matrices. The basic principle consists of two main steps. Gas Chromatography (GC) is a separation technique that allows for the various molecules in a mixture to separate in the chromatography column because of differences in their chemical properties. Subsequently, as the components exit from the column, these are fed into a Mass Spectrometer (MS), which breaks molecules into ionised species, and identifies these based on their mass-to-charge ratio. Usually, this identification is done by comparison against a spectral library of known chemical compounds.

A standardised GC-MS method which allows for the quantitation of chemical species at low levels in marine fuel oils and cutter stocks is available, ASTM D7845.[2] The standard method mentions

This test method is necessary to establish test conditions required for future ISO 8217:2010 as defined in section 5.5 and Annex B item (d).

However, the method is not widely used, and instead many laboratories have developed their own in-house proprietary GC-MS methods for fuel oil testing.

Various methods such as direct infusion, head space analysis, vacuum distillation, acid extraction, solid phase extraction (SPE), esterification, or pyrolysis GC-MS have been offered for investigative testing of fuel oil. The principal difference amongst these methods is the manner by which the sample is prepared or pre-treated prior to being actually injected into the GC-MS. As an example, head space analysis involves heating a sample in a sealed container at a certain temperature for a certain length of time, after which a portion is taken from the space above the liquid (i.e. the headspace) and injected into the GC-MS. As one might expect, the method detects compounds whose boiling point are within the range of the heating pre-treatment. Some of these pre-treatment methods could conceivably cause certain compounds to decompose, whilst others could introduce contaminants to the sample, if not carried out properly, which means that the components found may not be fully representative of the components initially present in the fuel.

Given the profusion of in-house methods, each could hence detect, and possibly quantify, different chemical compounds at different concentration levels. It would then be very difficult to make direct comparisons between test results from different laboratories. In the case of a dispute, it is often the case that a joint testing is called for, ideally to be carried out to the same method, and if possible at the same laboratory. Further, any in-house method would likely be challenged hence it is important the method is reviewed, agreed upon, and if possible, witnessed by the disputing parties.

Whilst GC-MS provides a sophisticated method to detect and quantify various chemical compounds in fuel oil, half the challenge is the interpretation of the test results. As far as we are aware, there are no published studies in scientific literature regarding the cause-and-effect relationship between any particular chemical compound or type of compounds, and the reported machinery damages, aside from those explicitly included in ISO 8217 (e.g. catalytic fines). ASTM D7845 notes

A great many types and concentrations of chemical species are found in marine fuel oils. A root cause relationship between the presence of such species or their concentration in fuels and any failure modes allegedly induced by the use of these fuels has not been established.

Annex B of ISO 8217 also notes that

… in most cases, sufficient data are not available with respect to the effects of any one specific material, or combinations thereof, on the variety of marine machinery systems in service, on personnel or on the environment.[3]

On the other hand, there have been many reports correlating certain chemical substances which have been found by GC-MS with vessels having suffered similar kinds of problems. Correlation does not necessarily equate to causation, however in general any such correlation becomes stronger with increasing sample size (i.e. similar machinery issues on vessels which have bunkered the same batch of fuel from the same supplier).

On a practical level, we would note that any joint testing should be for samples that represent the condition of the fuel as delivered to the vessel, and those would be the manifold drip samples taken during bunkering and indicated on the bunker delivery note.[4]

[1] ISO 8217: 2010 Fourth Edition

[2] ASTM D7845 – 17: Standard Test Method for Determination of Chemical Species in Marine Fuel Oil by Multidimensional Gas Chromatography/Mass Spectrometry

[3] ISO 8217: 2017 Sixth Edition

[4] In compliance with Standard Code of Practice for Bunkering SS600, in the case of Singapore

Please click below link to download our English/Chinese flyer.

On the use of Gas Chromatography (GC) – Mass Spectrometry (MS) for Testing Fuel Oil

Dr Rene Macahig has extensive experience in the fields of analytical, organic, and natural products chemistry. He is an expert in chemical analyses, structure elucidation, and instrumentation such as chromatography (HPLC, GC) and spectroscopy (NMR, MS, IR, UV-Vis).

Dr Macahig is a member of the American Chemical Society and Integrated Chemists of the Philippines.